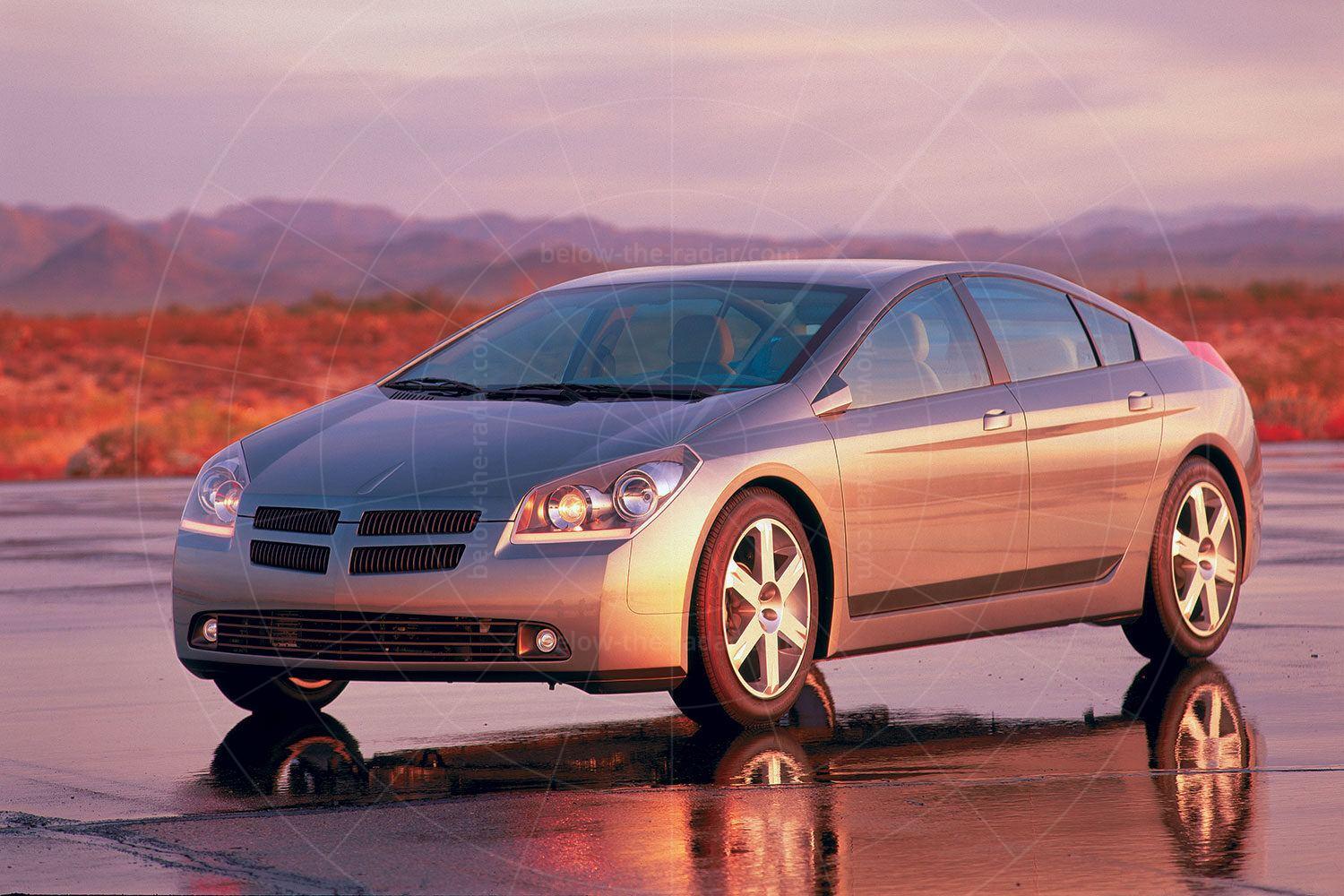

The fact that Dodge chose the 2000 Geneva motor show to first display its ESX3 concept was an indication of the company’s intention of taking on the Europeans at their own game. The Detroit motor show is traditionally the American car industry’s showcase for new cars and concepts, but in a bid to show that Dodge could compete on equal terms with marques such as BMW and Mercedes, the ESX3 burst on to the scene at the first (and arguably most important) European motor show of the year.

As the name suggested, the ESX3 was the third in a series of show cars; the first ESX had been unveiled in 1996 while the follow-up first saw the light of day in 1998. The series looked at how a hybrid car might be packaged, and they were developed as part of a US government/industry collaboration called the Partnership for a New Generation of Vehicles (PNGV). The aim of the project was to develop affordable transport that would also be more environmentally friendly than US car makers were used to. Considering the difference between the first ESX concept and its then-current production counterpart was a production cost of $60,000, while the difference between the ESX3 and the equivalent showroom car was just $7500, this third concept certainly showed promise.

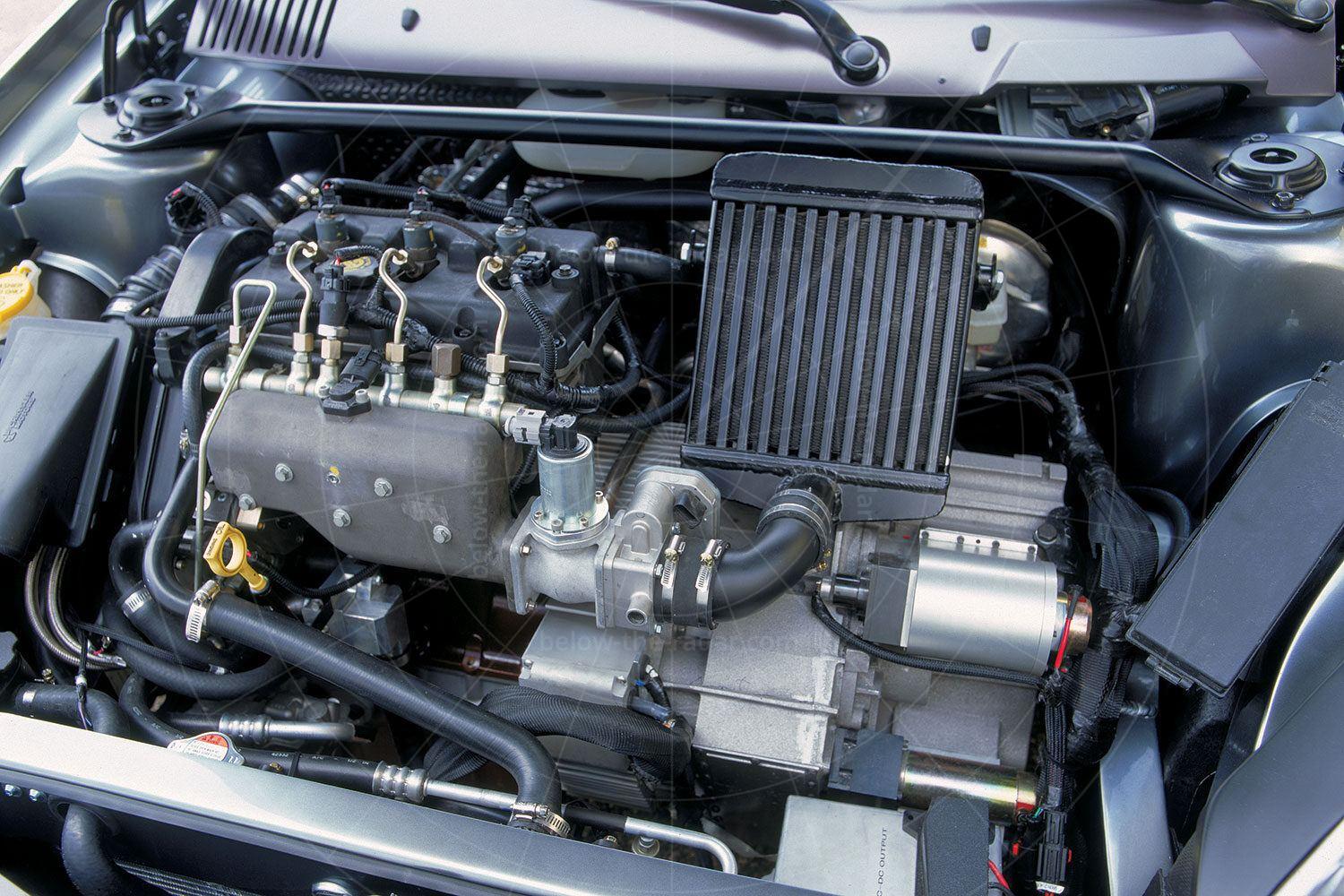

The key to the whole concept was the hybrid technology beneath the skin. Dodge referred to it as mybrid technology, which was short for mild hybrid, on account of it still putting the internal combustion engine first. But to help conserve fuel a small diesel engine was backed up by an electric motor powered by a state-of-the-art lithium-ion battery.

An electro-mechanical automatic transmission (dubbed EMAT) transmitted the power to the front wheels and thanks to the weight being reduced to a minimum, fuel consumption was reduced as far as possible. The PNGV goal had been set at 80mpg while the ESX3 managed to get to within 8mpg of this; further development could see the goal being achieved.

By reducing weight as much as possible, performance could also be maximised. Although no top speed was quoted for the ESX3, the acceleration time of 11 seconds to get from standing still to 60mph was pretty good, as just 94bhp was available with both the electric motor and the 1.5-litre diesel engine on song.

The bodyshell was made of injection-moulded thermoplastic and by the time the car was finished it weighed just 1020kg, which was pretty good going for a full-sized saloon capable of housing a family and their luggage. But it was recognised that a car such as the ESX3 would have to be fully equipped, so there was a high-performance video and audio system along with climate control. There was also a multimedia display which reduced the need for masses of switches throughout the cabin; instead everything could be controlled by a touch screen. It also meant everything could be personalised far more easily, according to what the driver and passenger wanted. By rethinking how these were built and integrated into the car it was possible to reduce weight even further.

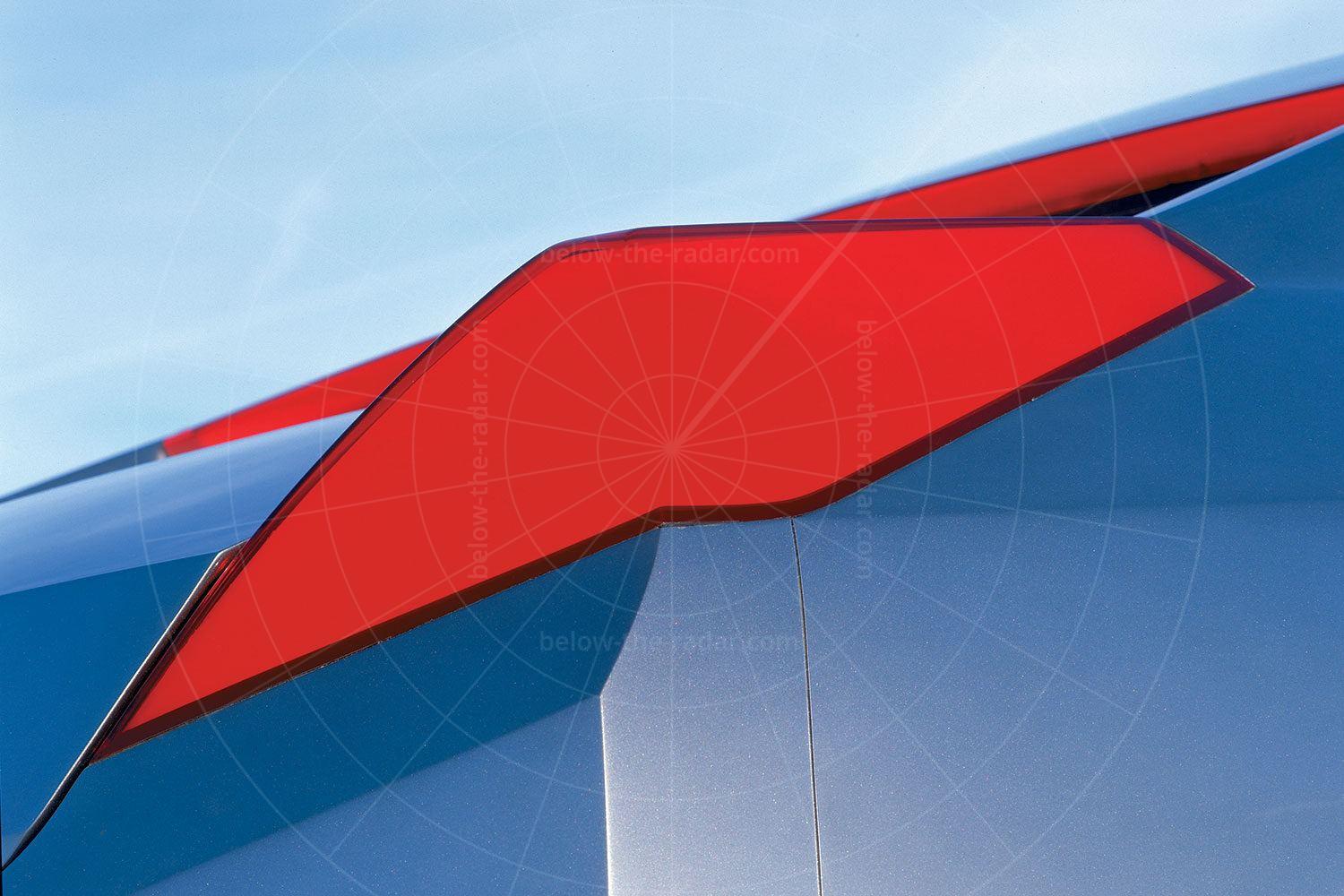

The problem with using advanced materials to keep weight down is that it’s not very easy to recycle them. Dodge aimed to tackle that comprehensively with the ESX3 and the result was a vehicle that achieved 80% recyclability. Clothing all this technology was a sharp suit that Dodge referred to as having ‘faceted design’. This was the look which was becoming popular globally – sheared surfaces and faceted angles gave a clean design without being bland. The tail lights gave a three-dimensional effect while also recalling the fins of Chrysler’s cars from the late 1950s, and the rear window sloped sharply before being abruptly truncated – something that was striking, if a little bizarre.

| Vital statistics | |

|---|---|

| Debut | Geneva 2000 |

| Engine | Front-mounted, 1.5-litre, diesel 4-cylinder, + rear-mounted electric motor |

| Transmission | Automatic |

| Power | 74bhp (diesel) + 20bhp (electric) |